About Ropes

- rope materials

- rope construction

- other important characteristics

- what size rope should I use?

- how much rope do I need?

rope materials

Rope materials generally are divided into two categories: natural and synthetic.

Natural fibers used specifically for rope include manila, sisal, hemp, and jute. Other common fibers, including cotton and linen, may also be used. Generally, natural fibers aren’t as strong as synthetic fibers: this may be an issue for heavier antennas, but they should be quite adequate for light wire antennas. Also, natural fibers tend to absorb water, which makes them less suitable as insulators. These would not be my first choice when synthetics are available, but they can certainly be used.

Synthetic fibers used for ropes are various types of plastics: nylon, polyester (Dacron® is duPont’s trade name), polyethylene, polypropylene, Kevlar®, and Dyneema® are common examples. Most will be good insulators, even if they get wet. Other properties vary widely with the details of the material.

Nylon is one of the most common rope materials. It tends to stretch somewhat under tension, which can help to soften the impact of sudden dynamic loads. Early types were not very resistant to sunlight, but most modern types from reputable manufacturers include UV inhibitors, and ropes should last at least 10 to 20 years in full sun.

Polyester (such as Dacron®) doesn’t stretch as much, and is more resistant to sunlight: it is often used on sailboats for those reasons. It tends to be more expensive than nylon, but in the last 20 years or so commercial makers have started making black polyester ropes specifically for antenna use in various sizes, and it is a good choice for long term use.

Polyethylene tends to be found more in twisted twines, such as those used for pulling wires through conduits or baling hay. Types designed for outdoor use (such as hay bales) have UV inhibitors and will survive 10+ years in the sun, while other types may show signs of deterioration in a matter of months.

Polypropylene is often used for ropes on boats, as it floats. It tends to be a bit more stiff, and, at least the older versions were not UV resistant.

Kevlar® and Dyneema® are newer materials designed for very high strength, such as replacing the steel cords in tires/tyres. While I personally haven’t found such strength necessary for my antennas, they do permit the use of thinner ropes.

These days I often see ropes marked as just “poly”, which I assume means they are made of whatever leftover or recycled plastics were available. They often are inexpensive, and should work for many uses, but don’t count on the strength or sunlight resistance if the actual type of plastic is not specified more accurately. (Years ago I climbed a tree to install a 160m antenna for another ham. It worked great while it was up, but in less than 2 years the rope decayed and the antenna fell down.)

rope construction

There are 4 common ways that ropes are made.

Monofilament means that the rope is a single strand of material. This is primarily used for nylon fishing lines, or for “string trimmers” for cutting weeds. They aren’t as flexible as a multistrand rope of the same size.

Twisted ropes are the most common, and have been used for hundreds of years with natural fibers, which can’t be manufactured in long continuous pieces the way modern plastics can be. While smaller twine and string may be made by just twisting a handful of fibers together, larger ropes generally are comprised of 3 yarns twisted together, each yarn possibly being comprised of several thinner ones. The ends of such ropes can start to unravel with use unless they are “whipped”, or have a knot tied in the end. Plastic types may start with a thin sheet (rather than separate fibers) that is then twisted into shape.

Braided ropes don’t unravel as much, and may provide a smoother surface. The braiding can be done several ways: when no strands cross over in the center of the rope, this is called a “hollow braid”. Strands can also be braided into flat straps or webbing for some applications, such as spreading the load when it is tied around a tree.

Kernmantle ropes have a dual construction: a bundle of fibers (“kern”) that run straight the length of the rope on the inside for strength, and a braided sheath (“mantle”) on the outside to protect the center strands from abrasion and hold them together. Parachute cord (“paracord”) and rock climbing ropes are the most common examples: many high performance ropes are made this way.

other important characteristics

We have mentioned strength, UV (sunlight) resistance, and stretching in the discussion so far. One other factor is how tight the fibers are wound (or braided) together. A “hard laid” rope has a smoother outside, which I find better for throwing over a tree branch as it doesn’t snag on the bark as much.

what rope size should I use?

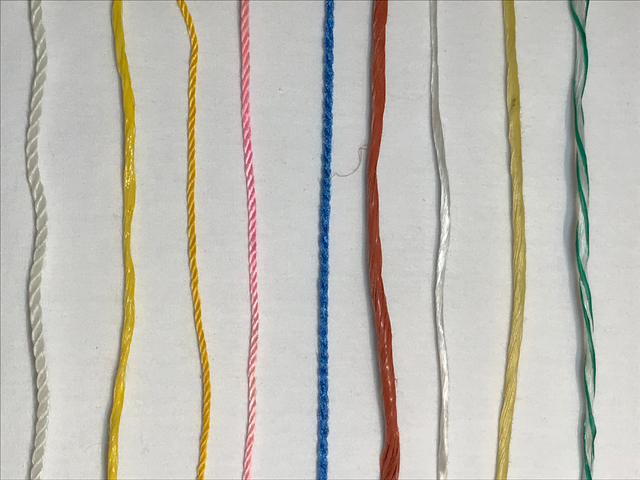

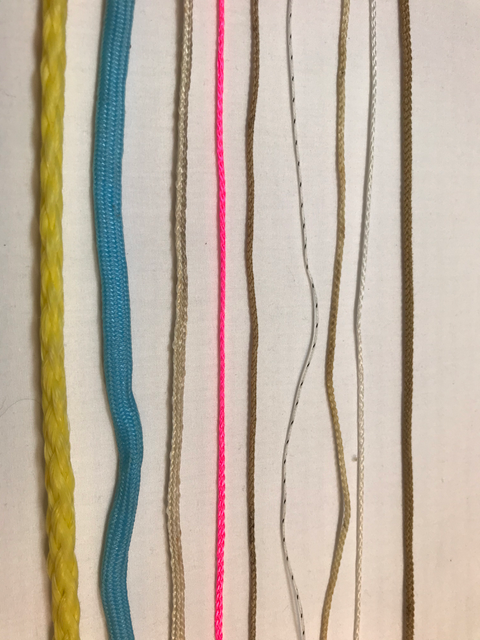

I’ve shown a range of rope sizes in the photos, and I’ve used all of these for antenna work. But some ropes are better for particular applications than others. For my particular style of antennas, breaking strength generally is not an issue: more important is how well I can work with it, tying (and untying!) knots easily, and what is easily available.

For lightweight portable antennas, my preference is something around 1.5 to 3mm ( 1/16 to 1/8 inch ). For tying off the ends of inverted vee dipoles, where there is little tension on the rope, I like some of the light twisted plastic twines, but practically anything will work.

For my rope throwing buckets, I prefer a braided rope, rather than twisted or kernmantle, with a relatively smooth finish (“hard lay”) to reduce friction when passing over tree branches. Braided mason’s twine works well for this.

More serious portable operation, such as Field Day, calls for the 4mm ( 3/16 inch ) hay baling twine, because it comes in a big spool and I have a lot of it: we may use 400m (400 yards) of rope to put up all the antennas. The baling twine gets used for antennas, mast guy ropes, putting up signs, and anything else we need. I have other types of rope, but nothing in that quantity, or at that low of a cost. Parachute cord is great stuff, but it feels too heavy for many of the antennas I put up.

For guying masts, it will depend on the height and wind load. 2mm ( 3/32 inch ) is sufficient for light masts holding dipoles. For larger masts, especially with a triband yagi on top, I’d use 4mm ( 3/16 inch ) paracord or baling twine (and make sure my anchors are strong enough if it is windy).

I’ve used the larger ropes, such as the 9mm ( 3/8 inch ) climbing rope, for working on towers or hoisting HF yagis. It is much easier to teach someone how to put a rope or webbing sling around the boom of a yagi than to tie a knot that won’t fail while it is being raised, and can be untied easily when it is in place.

In the end, the rope you use is an individual choice. First of all, see what is available to you, and what feels comfortable in your hand and is easy to work with. For permanent installations, consider the black braided polyester rope that is designed for antennas. For backpacking, consider the smaller options to save space and weight.

how much rope do I need?

That depends, of course, on what antenna(s) you are putting up and how high. But here is a guide how I would calculate the rope length for a set of inverted vee dipoles with the feedpoint up 10m ( 30 ft ) above the ground.

If the antenna is supported in a tree, I need a throwing rope. This needs to be at least twice the height of the tree, and preferably longer, to get the weight back down to the ground, and 3 times is better. So about 30 m ( 100 ft ).

Generally then I want a halyard to support the feedpoint (unless I am only putting up one antenna, so I don’t need to save my throwing rope for other purposes). Typically this would be at least twice the height of the antenna, or 20 m ( 60 ft ).

Each end of a dipole then needs to be tied off to some sort of anchor. If the anchor is at ground level, that would generally mean that the length of each dipole wire plus extension rope is about twice the height of the antenna, or 20 m (60 ft), if the rope is 30 degrees from horizontal. Now, dipole wires for 80m are going to be about 20 m long: if I want to keep the ends at half the height of the center, my ropes need to be as long as the antenna wire. If I am going to put up dipoles for the 80m, 40m, and 20m bands on the same feedpoint, then I would calculate the required rope lengths as:

- 80m: 2 ropes of 20 m ( 60 ft )

- 40m: 2 ropes of 10 m ( 30 ft )

- 20m: 2 ropes of 15 m ( 45 ft )

That’s a total of 120 m ( 370 ft ) if I use my throwing rope for the halyard. If I am using a portable mast, I’ll need more than that for the guy ropes as well (although I won’t need the throwing rope.)

In the field I often tie off the ends of the elements to convenient trees, bushes, or fence posts, or slope the elements at a steeper angle (including tying the ends of the 80m elements closer to the ground than ideal), so I may not need that much rope. And I can reuse some pieces: for example, once the center of the antenna has been raised, about half the halyard length is no longer needed, and could be used for tying the ends.

For backpacking I typically carry a 10 m (30 ft) throwing rope, along with at least 12 pre-cut pieces that are 3 m to 10 m (10 ft to 30 ft) long (enough for all the dipole wires I want to put up at the same time). However, it is not good practice to skimp on rope, as my antenna installations vary each time I set it up. Have enough extra in case the only available branch is up 15 m (50 ft), even if you don’t have enough coax to reach that high. I have used one of my dipole wires run vertically as part of my halyard when necessary. I may carry a spool of thinner rope as backup if needed. For other applications, if I am putting the antenna up higher, or tying the ends off more horizontal, then it can take more rope than this. When stringing an antenna between two trees, rather than as an inverted vee, I’d figure the rope + antenna length as the distance between the two trees plus twice the height of each tree, to provide enough to lower the antenna to the ground. Most of the ropes in my tub of baling twine are 15 – 40 m (50 to 120 ft), with lengths marked on them to make it easier to find the right size, and sometimes I use several tied together.

name usage and language

I have used “rope”, “twine”, and “line” in my writing to describe the material. “Rope” is a generic term, since often I’m not being specific about the size. “Twine” is basically a smaller size of rope: traditionally it has been lighter duty, often made by twisting many strands together all at once, but there are braided twines and other types as well. “Line” is also a generic term for whatever you are using at the moment. “String” generally connotes a smaller, weaker material, but I have avoided using that term to reduce confusion. (However, we would always refer to “fishing line” and “kite string” rather than “twine” or “rope”, even if they were otherwise identical: one of the quirks of my particular dialect of English.)